- DE

- EN

Digitisation can generally be understood as the conversion of analog data and information into a digital form.*

Neligan, Adriana; Engels, Barbara; Schaefer, Thilo; Schleicher, Carmen; Fritsch, Manuel; Schmitz, Edgar; Wiegand, Ralf (2021): IW-Gutachten: Digitalisierung als Enabler für Ressourceneffizienz in Unternehmen. Gutachten im Auftrag des Bundesministeriums für Wirtschaft und Energie. Institut der deutschen Wirtschaft. Berlin.

In the context of industrial value creation, the term digitisation is used when "analog service performance is replaced in whole or in part by service performance in a digital, computer-manageable model". Using the example of the digitisation of an engine control system, this means that analog control mechanisms (e.g., centrifugal governors) are replaced by sensors first measuring the basic parameters of the control system and transmitting them to a digital model of the control system. Using this digital model, the control parameters are calculated - with computer support - and then converted into control signals.*

Wolf, Thomas; Strohschen, Jacqueline-Helena (2018): Digitalisierung: Definition und Reife. In: Informatik Spektrum 41 (1), pp. 56–64. DOI: 10.1007/s00287-017-1084-8

Meanwhile, the term "Industry 4.0" stands for the fourth industrial revolution through networked and communicating systems*

Roth, Armin (Ed.) (2016): Einführung und Umsetzung von Industrie 4.0. Grundlagen, Vorgehensmodell und Use Cases aus der Praxis. 1st ed. 2016. Berlin: Springer Gabler.

and is often used synonymously with "digitisation". Although both terms refer to the connection of the physical world with the digital world, they differ in their perspective on this connection. For example, the term digitisation focuses on the process of change in which data, information and processes are transferred from the analog world to the digital world. Industry 4.0, on the other hand, aims at a state of complete digitisation of production in which the physical and digital worlds are interconnected in cyber-physical systems.*

VDI Zentrum Ressourceneffizienz GmbH (2017): Ressourceneffizienz durch Industrie 4.0. Potenziale für KMU des verarbeitenden Gewerbes. VDI Zentrum Ressourceneffizienz GmbH. Berlin.

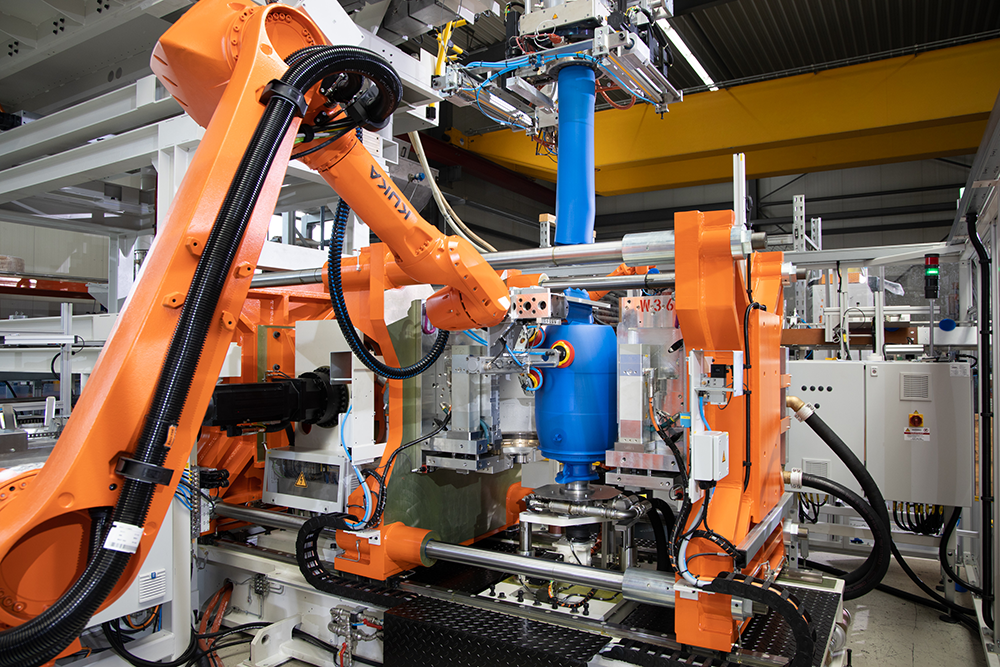

© VDI ZREIn order to remain competitive as a company in an environment with increasingly rapid product innovation cycles and growing diversity of variants, small and medium-sized enterprises (SMEs) must also address the challenges and opportunities of digitisation. In the manufacturing sector in particular, digitisation of production is being driven forward at an increasingly rapid pace on the way to Industry 4.0. Opportunities for cost savings through digitisation¬ arise across the entire product lifecycle: from raw material extraction through manufacturing, logistics, distribution and use to recycling of the goods produced. In this context, product development plays a prominent role due to its influence on innovations and processes throughout the entire product life cycle.

© VDI ZREIn order to remain competitive as a company in an environment with increasingly rapid product innovation cycles and growing diversity of variants, small and medium-sized enterprises (SMEs) must also address the challenges and opportunities of digitisation. In the manufacturing sector in particular, digitisation of production is being driven forward at an increasingly rapid pace on the way to Industry 4.0. Opportunities for cost savings through digitisation¬ arise across the entire product lifecycle: from raw material extraction through manufacturing, logistics, distribution and use to recycling of the goods produced. In this context, product development plays a prominent role due to its influence on innovations and processes throughout the entire product life cycle.

But in addition to the business benefits, digitisation also offers enormous potential for increasing resource efficiency.

The evaluation of past events in production processes and the collection of current process data represents the traditional reactive business intelligence (BI) currently used in many companies. However, to fully implement Industrie 4.0, data must be analysed and correlated in real time. This way, it becomes possible to clearly identify causes in order to subsequently eliminate them.

If artificial intelligence (AI) is also used, future problems can even be predictively avoided. A study is currently being conducted on behalf of the VDI Center for Resource Efficiency on the further potential for the use of AI in the manufacturing sector - especially in terms of resource efficiency.

The digitisation of processes is a precondition for Industry 4.0. In the following, two types of classification into individual digitisation levels are presented to illustrate the path toward Industry 4.0.

Get in touch for further information or help regarding the topic of "Digitisation".

Tel.: +49 (0)30 2759506-505

E-Mail: zre-industrie@vdi.de